February 24, 2026

What is the method of tunnel construction?

Tunnel construction is not a single method. It is a system of methods selected according to geology, groundwater, tunnel size, surrounding structures, safety requirements, and project schedule. In modern projects—especially rehabilitation, widening, portal modification, emergency repair, and lining removal—the demolition robot has become a highly practical tool. For tunnel demolition work, a demolition robot can improve precision, reduce risk to workers, and increase productivity in confined spaces where conventional equipment is difficult to use.

This article explains the main methods of tunnel construction, then focuses on how a demolition robot supports tunnel demolition, tunnel refurbishment, and selective removal operations. It also covers planning, safety, workflow, and equipment selection for a remote control demolition robot in tunnel environments.

1) Understanding tunnel construction methods

When people ask, “What is the method of tunnel construction?”, the correct answer is: it depends on the ground and the purpose of the tunnel. Common methods include:

A. Drill and Blast Method

This is widely used in hard rock tunnels. Workers drill blast holes, load explosives, blast, ventilate, remove muck, and install support. It is flexible and suitable for variable geology.

However, in urban areas or near sensitive structures, vibration control is critical. In these cases, a demolition robot may be used for secondary rock breaking, overbreak trimming, and controlled removal after blasting. A robot demolition approach helps improve shaping accuracy and reduces worker exposure near unstable faces.

B. Tunnel Boring Machine (TBM) Method

TBMs are used for long tunnels with consistent ground conditions. They are efficient and produce smooth tunnel profiles. But TBM projects also require support activities, including shaft work, cross-passage work, segment repair, and localized demolition. In maintenance or modification phases, a robotic demolition machine can remove damaged concrete or old lining sections without bringing in larger equipment.

C. Cut-and-Cover Method

Used for shallow tunnels, especially in cities. Engineers excavate from the surface, build the tunnel structure, and backfill. During widening, utility relocation, or structural replacement, a demolition robot can perform precise concrete removal around rebar and embedded utilities.

D. New Austrian Tunneling Method (NATM)

NATM relies on the surrounding ground strength and staged excavation with shotcrete, rock bolts, and monitoring. It is common in complex geology and urban tunnels. NATM often requires highly controlled trimming and support preparation. A remote control demolition robot is useful for removing unstable projections, damaged shotcrete, and sections requiring rework.

E. Pipe Jacking / Microtunneling

For smaller utility tunnels, trenchless methods reduce surface disruption. While this method is mostly mechanized, access shafts and receiving pits may need selective demolition. A demolition robot can assist in confined shaft demolition where operator safety is a major concern.

2) Why tunnel demolition is a special application

Tunnel demolition is very different from open-site demolition. Space is limited, visibility can be reduced, ventilation is critical, and the risk profile is higher. Tunnel projects may involve:

Removing damaged tunnel lining

Scaling loose rock

Demolishing internal concrete benches, ducts, or walls

Enlarging cross-sections

Opening cross-passages

Removing fire-damaged structures

Rehabilitating old tunnels for modern traffic loads

In these conditions, a demolition robot is often more suitable than large excavators because it is compact, precise, and remotely operated. A remote control demolition robot allows the operator to stand in a safer zone while the machine works at the face or sidewall. For contractors focused on tunnel rehabilitation, a demolition robot is no longer a niche tool—it is becoming standard equipment for high-risk, high-precision tasks.

3) How a demolition robot fits into tunnel construction and rehabilitation

A tunnel project may use multiple methods during its lifecycle. For example, the main excavation may be done by drill and blast, while finishing corrections and rehabilitation later are completed by a demolition robot. Here is where the demolition robot adds value:

3.1 Selective concrete removal

Tunnel linings often require partial removal, not full demolition. A robotic demolition machine equipped with a breaker can remove damaged concrete while preserving surrounding sections. This is especially useful when repairing water ingress zones, spalling concrete, or fire-damaged linings.

3.2 Rock scaling and trimming

After excavation or blasting, loose rock must be removed. A demolition robot can perform controlled scaling in zones where manual scaling is unsafe. A robot demolition setup also helps shape the profile before shotcrete application.

3.3 Working in confined zones

A remote control demolition robot can operate in narrow tunnels, cross-passages, and shafts where conventional equipment has poor maneuverability. Its compact footprint and articulated arm make it effective for tunnel demolition tasks in restricted geometry.

3.4 Reduced worker exposure

Tunnel demolition creates hazards: falling rock, dust, vibration, noise, and unstable surfaces. A demolition robot keeps operators away from the immediate impact zone. This is one of the strongest reasons contractors choose a demolition robot for tunnel demolition.

3.5 Multi-tool flexibility

Many tunnel projects require breaking, scaling, crushing, and mucking coordination. A robotic demolition machine can be equipped with attachments such as breakers, crushers, buckets (in some models), or scalers. This makes the demolition robot useful across multiple stages of tunnel rehabilitation.

4) Typical tunnel demolition workflow using a demolition robot

A successful tunnel demolition project is about process control, not just machine power. Below is a practical workflow for a demolition robot application in tunnel construction rehabilitation:

Step 1: Site survey and structural assessment

Engineers inspect the tunnel lining, rock condition, reinforcement layout, utilities, and groundwater conditions. They identify what must be removed and what must remain.

Step 2: Method statement and sequencing

The contractor defines the demolition zones, support requirements, ventilation plan, dust suppression, and spoil removal path. This is where the robot demolition sequence is designed to avoid overbreak.

Step 3: Temporary support installation

Before demolition starts, temporary supports may be installed depending on the structural risk. Tunnel demolition should never begin without confirming stability.

Step 4: Demolition robot positioning

The demolition robot is moved to the work area and stabilized. For steep gradients or wet conditions, traction and anchoring are checked carefully. A remote control demolition robot is then tested for communication reliability and emergency stop function.

Step 5: Controlled demolition

The operator uses the demolition robot to remove concrete or rock layer by layer. For lining repair, the demolition robot works in passes to prevent shock damage to adjacent sections. A robotic demolition machine can deliver consistent impact with better control than manual jackhammers.

Step 6: Debris removal and inspection

After each stage, debris is removed and the exposed surface is inspected. Engineers verify that the demolition robot has achieved the required depth and boundaries.

Step 7: Support, repair, or reconstruction

Once tunnel demolition is complete, crews install rock bolts, mesh, shotcrete, waterproofing, or new lining sections as required.

5) Key advantages of a remote control demolition robot in tunnel demolition

A remote control demolition robot is particularly well suited to tunnel environments because tunnel work combines confined space risk with heavy-duty removal requirements.

Safety advantages

Keeps the operator away from unstable rock or concrete

Reduces manual breaker exposure (vibration and fatigue)

Improves safety in low-headroom zones

Supports work in hazardous post-fire or water-damaged tunnels

For safety-led contractors, the demolition robot is often the preferred choice when tunnel demolition conditions are unpredictable.

Productivity advantages

Faster setup than larger equipment in confined spaces

Higher precision than handheld tools

Less rework due to controlled removal

Continuous performance in difficult positions

A robot demolition strategy can significantly improve shift productivity, especially when access time is limited.

Quality advantages

Better profile control for tunnel widening

Precise removal around reinforcement

Reduced overbreak in repair zones

Cleaner surfaces for shotcrete and lining repairs

This is why many engineers specify a robotic demolition machine in tender methods for tunnel rehabilitation work.

6) Choosing the right demolition robot for tunnel applications

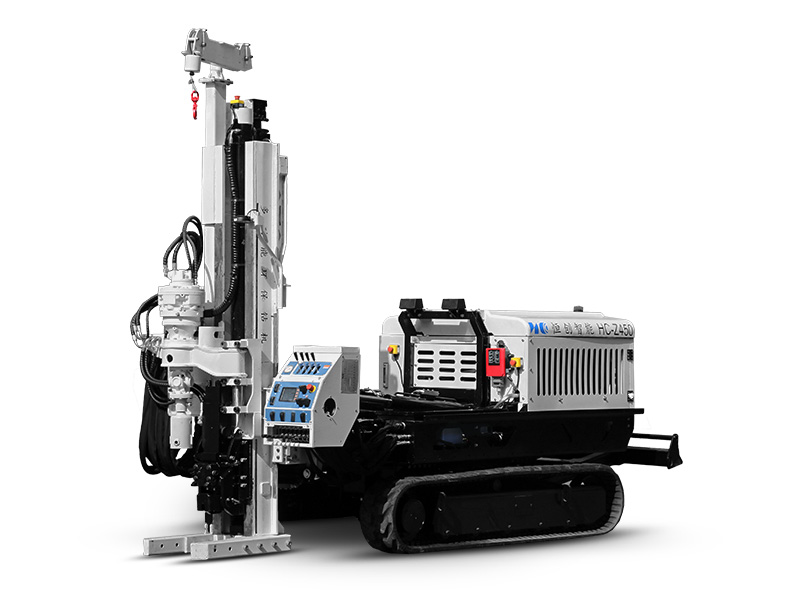

Not every demolition robot is ideal for tunnel work. Buyers should evaluate the following:

Reach and arm geometry

Tunnel sidewalls, crowns, and invert areas require different angles. A demolition robot with flexible arm articulation improves access and reduces repositioning.

Power-to-size ratio

Tunnel access may be narrow, but the material may be very hard. A demolition robot should offer strong hydraulic performance in a compact frame.

Remote control reliability

A remote control demolition robot must maintain stable control in dusty, wet, and signal-challenging environments. Emergency stop response and operator visibility are essential.

Attachment compatibility

For tunnel demolition, a demolition robot may need a breaker, crusher, or scaling tool. Confirm hydraulic flow and attachment matching before deployment.

Transport and setup

A robotic demolition machine used in tunnel construction should be easy to transport through portals, shafts, or service routes.

7) Practical considerations: dust, ventilation, and support coordination

Tunnel demolition is not only about the machine. Even the best demolition robot performs poorly without proper environmental control.

Ventilation: Essential for dust, fumes, and visibility

Dust suppression: Water spray and extraction improve safety and equipment life

Lighting: Good visibility helps the remote control demolition robot operator work precisely

Ground support coordination: Demolition and support crews must work in synchronized sequences

Spoil logistics: Debris removal bottlenecks can limit the productivity of the demolition robot

A tunnel contractor that integrates the demolition robot into a full operational plan will see better results than one that treats it as a standalone tool.

8) Is tunnel demolition part of tunnel construction?

Yes. In modern practice, tunnel construction includes new excavation, modification, rehabilitation, and lifecycle maintenance. Many tunnel projects today are upgrades rather than greenfield builds. That means tunnel demolition is often a core stage of the construction process.

For this reason, the demolition robot has become increasingly important. Whether the project involves cross-passage enlargement, lining replacement, profile correction, or structural rehabilitation, a demolition robot provides a safer and more controlled method. A robot demolition approach is especially valuable in urban tunnels, transport tunnels, mining tunnels, and utility tunnels where downtime and safety constraints are strict.

Conclusion

So, what is the method of tunnel construction? The method depends on geology, depth, and project purpose—common approaches include drill and blast, TBM, NATM, cut-and-cover, and trenchless systems. But in the real world, tunnel projects also require demolition, correction, and rehabilitation. That is where the demolition robot plays a critical role.

For tunnel demolition, a demolition robot offers precision, safety, and flexibility in confined spaces. A robotic demolition machine can remove damaged lining, scale rock, and support selective tunnel modifications with less worker exposure. And with a remote control demolition robot, contractors can complete high-risk tunnel demolition tasks more safely and efficiently.

If your project involves tunnel repair, upgrading, or structural modification, integrating a demolition robot into the method statement is often one of the most effective decisions you can make.

FAQs

1) Can a demolition robot be used in active traffic tunnels during rehabilitation?

Yes, in many cases a demolition robot can be used during planned closures or controlled maintenance windows. Its compact size and precision make it suitable for staged work, but traffic management, ventilation, and safety barriers must be planned carefully.

2) What is the difference between a demolition robot and a standard excavator breaker in tunnel demolition?

A demolition robot is generally smaller, more precise, and remotely operated, which is a major advantage in confined tunnel spaces. A standard excavator breaker may provide high impact energy, but access, safety distance, and maneuverability are often more limited in tunnel demolition.

3) Is a remote control demolition robot only for concrete, or can it also handle rock?

A remote control demolition robot can handle both concrete and rock depending on the model, hydraulic power, and attachment selection. It is commonly used for tunnel lining removal, rock scaling, and controlled breaking in rehabilitation and enlargement projects.