In construction demolition operations, selecting the appropriate demolition method is directly related to personnel safety, construction efficiency, and environmental impact. So, why should demolition robots be prioritized in the field of construction demolition?

Traditional manual demolition is not only inefficient but also faces significant safety risks. When construction workers work at heights or demolish solid constructions, they may encounter dangers such as falls and being hit by objects at any time. At the same time, the dust and noise pollution generated by manual demolition seriously affect the surrounding environment and residents' lives.

Mechanical forced demolition has poor operational accuracy and is prone to excessive damage to surrounding constructions. Its environmental adaptability is limited, making it difficult to operate in complex scenarios such as basements and narrow spaces; the bulky body and limited movement of the mechanical arm, as well as the operation relying on manual experience with insufficient safety protection, all bring problems. Operators need to control it at close range, facing the risk of falling components and wall collapse, which may easily lead to safety accidents. Demolition robots can effectively avoid the problems of traditional manual demolition, such as low efficiency, high risk, and heavy pollution, as well as the problems of mechanical forced demolition, such as poor accuracy, limited adaptability, and insufficient protection. With high precision, strong adaptability, and reliable safety guarantees, they have become the ideal choice in the field of construction demolition.

Safety Guarantee

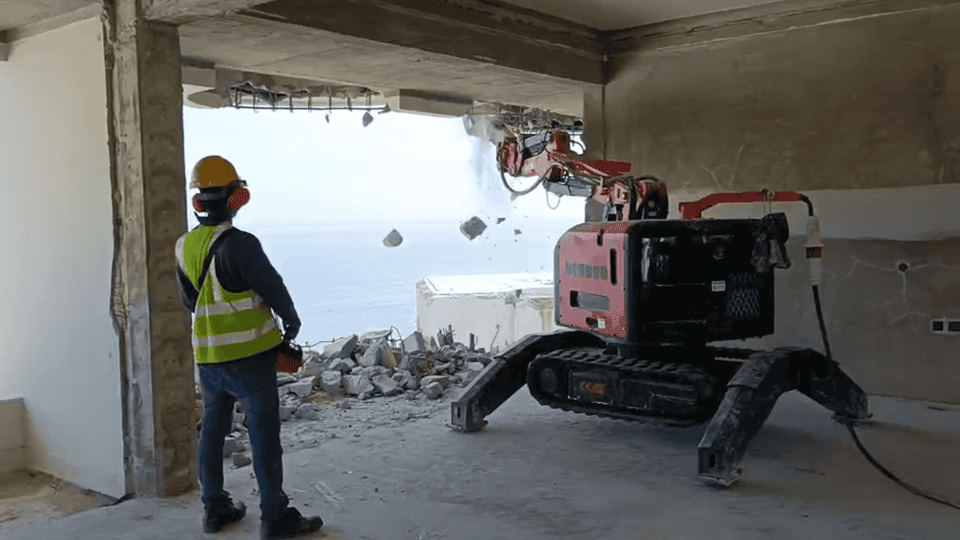

Demolition robots are equipped with advanced remote control systems, allowing operators to control the operation from a safe area. This avoids direct exposure to dangerous environments and gets rid of the risks of falling components, wall collapse, and flying debris at close range, providing a reliable safety barrier for construction workers.

Operational Efficiency

The high-frequency and high-impact operation mode of demolition robots can quickly break various building materials. The unique three-section arm system provides excellent flexibility and operating range. Whether it is demolishing walls, floors, or handling complex structural projects, it can provide the power and precision required to complete the work efficiently.

Environmental Performance

Demolition robots enable construction to be carried out with no vibration, low noise, no exhaust gas, and no dust, minimizing the impact on the surrounding environment. Electric operation has no exhaust emissions. Compared with traditional equipment such as pneumatic picks and excavators, it can significantly reduce dust and vibration, and is especially suitable for urban environments, areas near residential areas, and other scenarios with strict control over noise and environmental protection.

Multi-Attachment Adaptability

There are various types of construction renovation and demolition, including the demolition of reinforced concrete beams and columns, building storey reduction, and indoor renovation. Through modular attachment interfaces, demolition robots can quickly replace various attachments such as concrete hydraulic shears, steel shears, milling heads, and buckets in a short time. They can be flexibly customized according to different operational needs, greatly enhancing the versatility and adaptability of the equipment.

Flexible Accessibility

Demolition robots have a compact body and can operate in areas that most traditional demolition equipment cannot reach. They can easily climb over ruins and climb stairs. With light weight and small size, they can be transported between floors via standard elevators, providing extremely high operational flexibility for multi-storey construction projects and showing super strong adaptability in complex demolition scenarios.

In the future, the position of demolition robots in the field of construction demolition will become more core. In addition to existing conventional construction demolition, demolition robots will also play an important role in the demolition of special environments, such as the decommissioning and demolition of nuclear power plants, the demolition of chemical facilities, and other fields with extremely high requirements for safety and environmental protection. Moreover, with the development of construction industrialization, the demand for precise demolition of prefabricated components will increase. Demolition robots, relying on their high-precision operation capabilities, will become the preferred equipment for such operations.

It is foreseeable that demolition robots will not only become the mainstream equipment in the construction demolition industry but also promote the entire industry to transform towards intelligence, greenization, and safety. They will become an indispensable key force in the process of urban renewal and construction renovation, reshaping the operation mode and development pattern of the construction demolition field.