The construction industry, long characterized by manual labor and heavy machinery, is undergoing a transformative shift with the integration of robotics. From automated bricklayers to AI-powered drones, robotics is redefining efficiency, safety, and precision in construction. Among these innovations, robotic demolition stands out as a groundbreaking application, offering solutions to some of the sector’s most persistent challenges. This article explores the role of robotics in construction, with a focus on demolition robots, key industry players, and future trends.

Construction robotics is no longer a futuristic concept—it’s a reality reshaping worksites globally. Factors driving this adoption include:

Labor shortages: Aging workforces and declining skilled labor availability.

Safety demands: Reducing human exposure to hazardous tasks.

Sustainability goals: Minimizing waste and emissions.

Efficiency needs: Accelerating project timelines with precision.

Robotic systems now handle tasks like welding, painting, material transport, and even complex demolition. Let’s delve into one of the most impactful applications: robotic demolition.

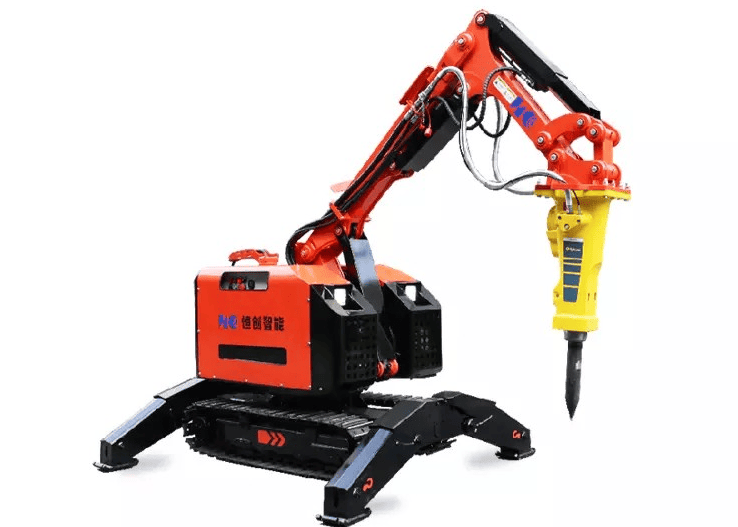

Robotic demolition involves using remote-controlled or autonomous machines to dismantle structures safely and efficiently. Unlike traditional methods relying on excavators or manual labor, these robots excel in confined spaces, high-risk environments, and precision tasks.

Remote Operation: Operators control machines from a safe distance using joysticks or VR interfaces.

Modular Attachments: Interchangeable tools like hydraulic breakers, crushers, and shears.

Sensors and AI: LiDAR, cameras, and collision-avoidance systems enhance accuracy.

Electric vs. Diesel: Growing adoption of electric models for reduced emissions.

Several manufacturers dominate the robotic demolition sector. Below, we highlight key players and their flagship models.

Brokk, a Swedish pioneer, offers compact, agile machines ideal for indoor demolition. Popular models include:

Brokk 100: Weighs 1,000 kg, suited for small spaces.

Brokk 400: A mid-sized powerhouse with 400 kg impact force.

Brokk 500: Heavy-duty model for reinforced concrete.

Advantages: Dust suppression systems, low noise, and high maneuverability.

The Husqvarna DXR Series emphasizes versatility and eco-friendliness. The DXR 140 and DXR 310 are electric-powered, reducing carbon footprints.

Features: Zero emissions, remote operation up to 500 meters, and 360-degree rotation.

Emerging brands like Hitech focus on AI integration. Their robots use machine learning to optimize demolition paths and material sorting.

| Model | Power Source | Weight (kg) | Reach (m) | Applications |

|---|---|---|---|---|

| Brokk 400 | Diesel/Electric | 4,500 | 8 | Concrete, steel structures |

| Husqvarna DXR 310 | Electric | 3,100 | 10 | Indoor demolition, recycling |

| Hitech 200D | Electric | 2,600 | 6 | Precision demolition, tunneling |

Workers avoid exposure to collapsing debris, dust, and hazardous materials.

Robots work continuously without fatigue.

Brokk machines can reduce project timelines by up to 40% compared to manual methods.

Electric models produce zero emissions.

Precision reduces material waste by 30%, aiding recycling efforts.

While demolition robots grab headlines, other innovations are equally transformative:

SAM100 (Semi-Automated Mason) lays 3,000 bricks/day vs. a human’s 500.

Apis Cor prints entire concrete houses in 24 hours.

Self-driving bulldozers (e.g., Caterpillar’s CAT Command) grade land with GPS precision.

Drones survey sites and monitor progress.

High Initial Costs: Demolition robots can exceed $200,000.

Technical Skill Gaps: Operators require specialized training.

Limitations in Complexity: Robots struggle with highly irregular structures.

Trends to watch:

AI Integration: Machines that adapt to dynamic environments.

Swarm Robotics: Multiple robots collaborating on large tasks.

Sustainable Tech: Solar-powered robots and biodegradable materials.

Q1: How much does a demolition robot cost?

A: Prices range from 500,000 for heavy-duty units.

Q2: Can robots work in confined spaces?

A: Yes! Models like Brokk 100 are designed for tight spaces.

Q3: Are demolition robots eco-friendly?

A: Electric models (e.g., Husqvarna DXR) produce zero emissions and less noise.

Q4: How do robots compare to traditional excavators?

A: Robots offer superior precision and safety but may lack the raw power of large excavators.

Q5: What industries use demolition robots?

A: Construction, nuclear decommissioning, shipbuilding, and tunneling.

Robotic demolition is just one facet of a broader revolution in construction. As technology advances, robots will become faster, smarter, and more accessible—ushering in an era where human and machine collaboration builds the future. From tearing down skyscrapers to 3D-printing homes, the possibilities are limitless.