In the mining industry, efficiency and safety are critical when it comes to material handling and processing. One essential piece of equipment that plays a significant role in these operations is the Rockbreaker Boom System. Whether you are dealing with material blockages in open-pit mines or underground operations, a well-chosen Hydraulic Rock Breaker Boom System can drastically improve productivity and reduce downtime. But with many options available, how do you choose the right Rockbreaker Boom for your needs?

This guide will provide you with in-depth insights into Rockbreaker Boom Systems, focusing on key factors for selection, performance comparisons, and available technologies. We'll also highlight how Hitech offers cutting-edge solutions tailored for the mining industry.

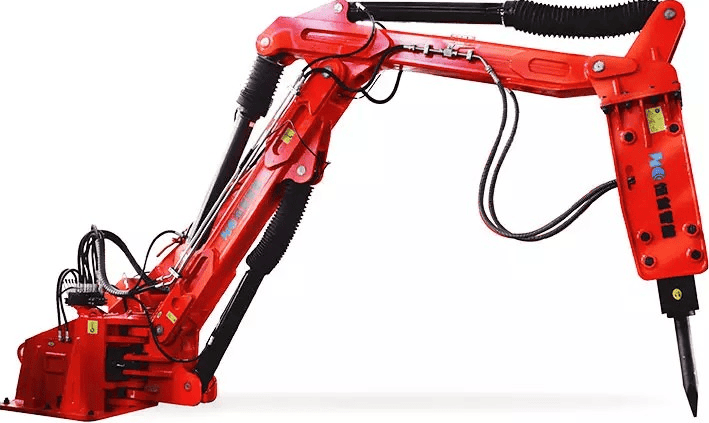

A Rockbreaker Boom System is an advanced, intelligent piece of equipment that integrates mechanical, electrical, and hydraulic technologies. Its primary function is to break oversized rocks or material blockages at critical points such as the feed inlet of crushers or the screen openings in mining operations.

The Rockbreaker Boom System is indispensable in mining operations. Consider the following applications:

Different mining operations require different types of Rock Breaker Machines. For instance:

The hydraulic power determines the force exerted by the breaker, while the boom's reach defines how far it can operate. Consider the size of the material to be broken and the distance from the operator to the target.

Ensure the Rockbreaker Boom System can be seamlessly integrated with your existing crusher or feeder system. Compatibility is crucial to avoid operational disruptions.

Safety is paramount in mining. Look for systems with remote operation capabilities, multi-sensor monitoring, and emergency stop functions.

Choose a system built with durable materials designed for harsh mining environments. Additionally, consider the availability of spare parts and ease of maintenance.

Hitech's Hydraulic Rock Breaker Boom Systems are equipped with cutting-edge features, such as:

Hitech offers a variety of models to suit different mining applications:

By minimizing downtime and improving material flow, Hitech systems significantly reduce operational costs.

With over 20 years of experience, Hitech provides comprehensive support, including installation, maintenance, and training.

| Feature | Rockbreaker Boom System | Traditional Methods |

|---|---|---|

| Safety | Remote operation reduces risks. | High risk of worker injury. |

| Efficiency | Continuous material flow; faster blockage clearance. | Frequent delays due to manual clearing. |

| Precision | Hydraulic systems ensure targeted breaking. | Limited precision with manual tools. |

| Durability | Built for extreme environments. | Frequent wear and tear. |

Choosing the right Rockbreaker Boom System is crucial for optimizing operations in the mining industry. Consider your specific application needs, hydraulic power, compatibility, and safety features when making your decision.

Among the many brands available, Hitech Intelligent offers some of the most advanced and reliable solutions tailored for mining applications. With over two decades of expertise, Hitech’s systems, such as the HCBM-2520D and HCBMR-6535D, provide unmatched performance, durability, and safety.

To learn more about Hitech’s Rockbreaker Boom Systems, visit their official website at www.hcrot.com. Let Hitech help you revolutionize your mining operations with state-of-the-art robotic technology.

FAQ of Rockbreaker Boom Systems

Q: What are the main applications of a Rock Breaker Boom System?

A: 1. Breaking oversized rocks or boulders that block the crusher feed. 2.Improving crusher efficiency and preventing downtime caused by blockages. 3. Enhancing workplace safety by eliminating the need for manual rock breaking.

Q: How do I choose the right Rock Breaker Boom System?

A: The size and type of crusher.

The hardness and size of the material to be broken.

The reach and coverage area required for the arm.

The operating environment and workload.

Q: Is the system customizable for specific applications?

A: Yes, Rock Breaker Boom Systems can be customized to meet specific operational needs, including arm length, breaker size, rotation capabilities, and mounting options to suit different crusher types and layouts.