Soil drilling, also known as geotechnical drilling or soil boring, is a critical process in civil engineering, environmental studies, and construction. It involves penetrating the earth’s subsurface to collect soil or rock samples, install monitoring equipment, or assess ground conditions. This procedure relies on specialized machinery called soil drilling machines or geotechnical drilling rigs, which are designed to handle diverse terrains and soil compositions. In this article, we explore the fundamentals of soil drilling, the types of equipment involved, their applications, and the technology driving modern geotechnical investigations.

Soil drilling serves as the backbone for projects requiring subsurface analysis, such as building foundations, road construction, mineral exploration, and environmental assessments. By extracting soil samples at varying depths, engineers and geologists gain insights into soil stability, groundwater levels, contamination risks, and load-bearing capacity.

Construction Projects: Assessing soil strength for foundations, bridges, and tunnels.

Environmental Studies: Detecting pollutants or monitoring groundwater quality.

Mining and Exploration: Identifying mineral deposits or fossil fuels.

Infrastructure Maintenance: Evaluating soil conditions for pipeline or utility installations.

Drilling rigs are categorized based on their operational mechanisms and applications. Below, we break down the three main types of drilling rigs and four common drilling machines used in soil drilling.

Rotary Drilling Rigs

Use a rotating drill bit to cut through soil and rock.

Ideal for deep drilling in hard formations.

Common in oil, gas, and geothermal projects.

Percussion (Cable Tool) Drilling Rigs

Employ a heavy chisel-like bit that repeatedly strikes the ground.

Suitable for shallow wells and unconsolidated soils.

Known for simplicity and low cost.

Vibratory Drilling Rigs

Utilize high-frequency vibrations to penetrate loose or sandy soils.

Efficient for environmental sampling and soil testing.

| Type | Description | Applications |

|---|---|---|

| Soil Test Drilling Machine | Lightweight rig for shallow sampling | Soil testing, environmental studies |

| Geotechnical Drilling Rig | Heavy-duty rig for deep boreholes | Construction, mining |

| Auger Drilling Machine | Uses helical screws to lift soil | Foundation studies, agriculture |

| Sonic (Vibratory) Drill | High-frequency vibrations for fast drilling | Urban areas, sensitive sites |

Modern drilling rigs integrate four essential systems to ensure efficiency and safety:

Power System:Provides energy to operate the rig (e.g., diesel engines or electric motors).

Hoisting System:Manages the lifting and lowering of drill pipes and tools.

Rotary System:Drives the rotation of the drill bit (critical for rotary rigs).

Circulation System:Pumps drilling fluid (e.g., water or mud) to cool the bit and remove cuttings.

The geotechnical drilling process involves several methodical steps:

Site Investigation: Review geological maps and survey the area.

Equipment Setup: Choose a rig based on soil type and project requirements.

Drilling: Extract soil samples at predetermined depths.

Sample Analysis: Test samples for composition, density, and contamination.

Reporting: Compile data to guide engineering decisions.

| Feature | Geotechnical Drilling Rig | Soil Testing Drilling Machine |

|---|---|---|

| Max Depth | 300+ meters | 30–50 meters |

| Mobility | Truck-mounted or trailer | Portable, hand-operated |

| Power Source | Diesel/Electric | Electric/Battery |

| Primary Use | Construction, mining | Environmental sampling |

| Cost | High (500k) | Low (20k) |

Q1: What is a geotechnical drill rig?

A: A geotechnical drill rig is a heavy-duty machine used to drill deep into the earth for soil sampling, mineral exploration, or foundation testing.

Q2: What are the three main types of drilling rigs?

A: Rotary, percussion, and vibratory drilling rigs.

Q3: What are the four types of drilling machines?

A: Soil test drilling machines, geotechnical rigs, auger drills, and sonic drills.

Q4: What are the 4 systems of a drilling rig?

A: Power, hoisting, rotary, and circulation systems.

Q5: What is the machine that makes holes in soil?

A: A soil drilling machine or auger drill.

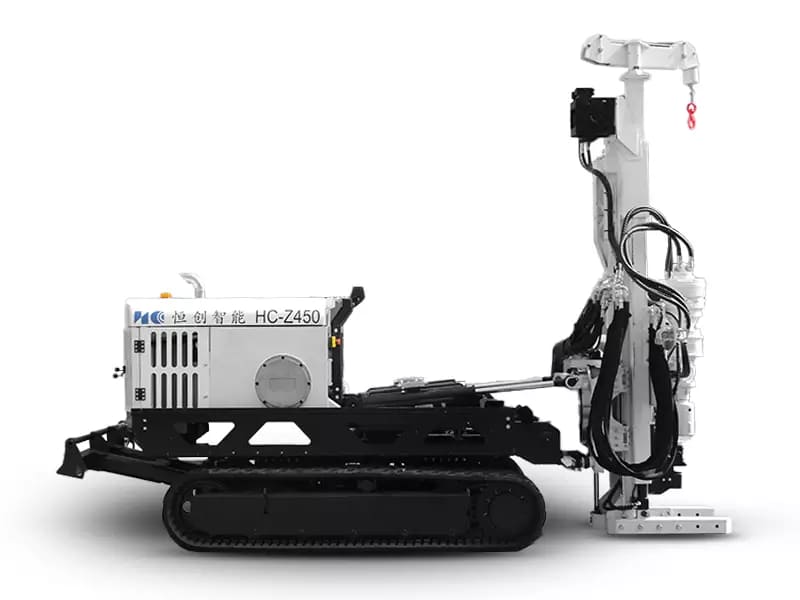

Soil drilling is indispensable for ensuring the safety and feasibility of construction and environmental projects. With advancements in technology, modern rigs like Hitech’s geotechnical drilling machines offer enhanced precision, mobility, and adaptability. Whether for soil testing or deep boreholes, choosing the right equipment is crucial.

For cutting-edge drilling solutions, visit https://www.hcrot.com/ to explore a range of rigs tailored to your project needs.