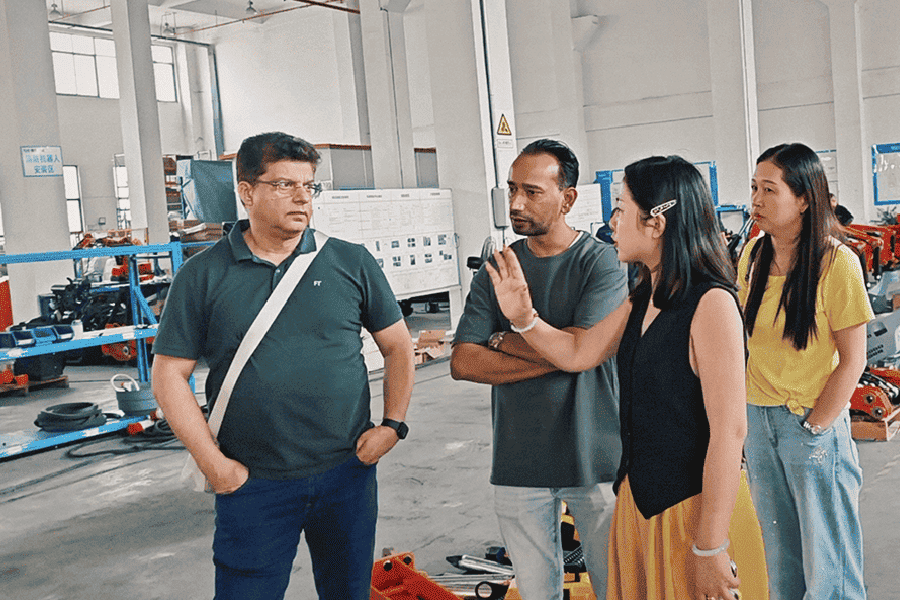

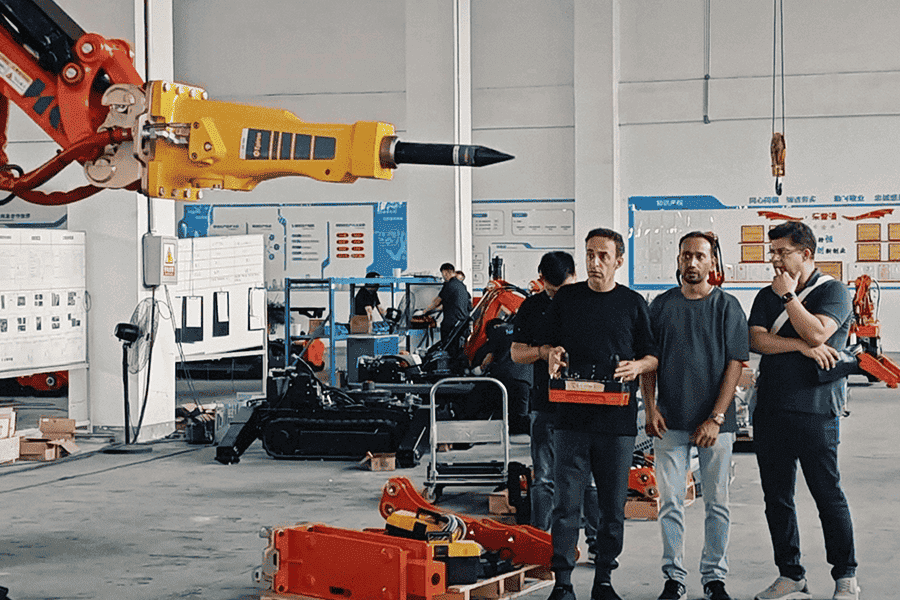

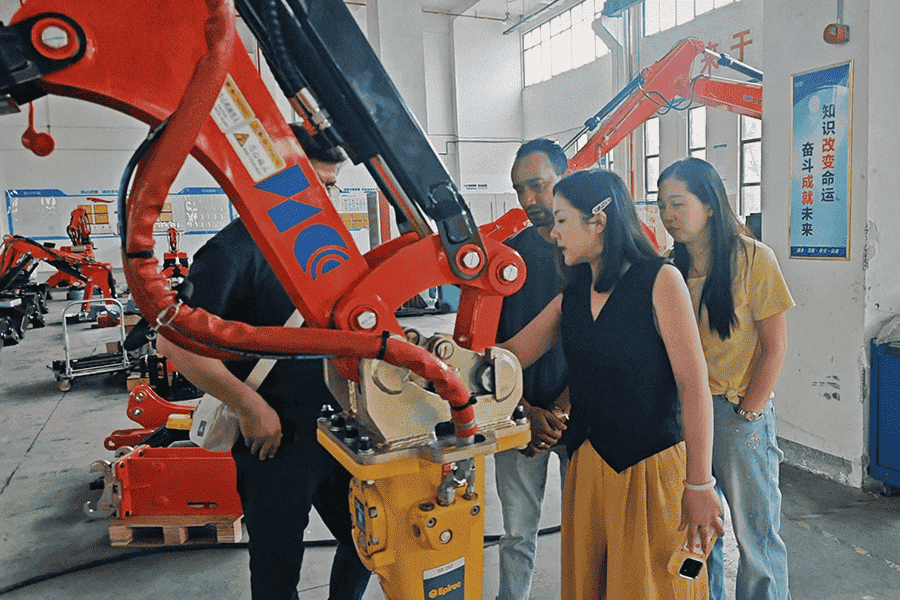

On June 3, 2025, a delegation of Middle Eastern business partners visited the headquarters of Anhui Hitech Intelligent Equipment Co., Ltd. They focused on inspecting the HCR series of small and medium-sized intelligent demolition robots and customized accessory systems. The customers gained in - depth understanding of the product's technological breakthroughs and industry application potential in high - temperature and high - risk scenarios, laying a solid foundation for the deepening cooperation between the two parties.

The visit of the Middle Eastern business delegation to Anhui Hitech Intelligent Equipment Co., Ltd. is of great significance. With the accelerating global industrial automation and intelligentization process, the application prospects of special demolition robots in high - temperature and high - risk industries such as aluminum electrolysis are extremely broad. In the future, Anhui Hitech Intelligent Equipment Co., Ltd. will carry out closer cooperation with the Middle East's aluminum electrolysis industry. On the one hand, the company will further optimize product performance according to the actual working conditions and customer needs in the Middle East region, and launch more customized solutions to help Middle Eastern aluminum electrolysis enterprises improve production efficiency, reduce safety risks, and improve the working environment. On the other hand, this cooperation will also help the company explore a broader international market and promote the application and development of special demolition robot technology on a global scale.

It is believed that with the joint efforts of both parties, special demolition robots will surely shine in the Middle East's aluminum electrolysis industry, injecting new vitality into the industry's transformation and upgrading, and creating a new situation of human - machine collaboration and intelligent operation in high - temperature and high - risk industrial scenarios.

Core Parameters:

Weight: 750kg (excluding attachments)

Dimensions: Transport width 600mm × height 972mm × length 1500mm

Power: Driven by a 7.5kW motor, emission - free and low - noise

Function Highlights: It can be transported through standard doorways and elevators, suitable for operations in narrow spaces. Specifically designed for toxic, flammable, and explosive environments, it can replace manual work.

Applicable Scenarios: Indoor demolition, precise crushing in dangerous environments

Core Parameters:

Power: Driven by an 18.5kW motor, energy - saving and environmentally friendly

Function Highlights: It features a bionic three - section arm design for comprehensive operation coverage. It can be wirelessly remotely controlled, suitable for high - temperature and high - dust environments.

Application Cases: Cleaning of metallurgical build - ups, demolition of narrow industrial buildings

Core Parameters:

Power: Driven by a 22kW motor, with a load - feedback electro - hydraulic proportional system

Functions: Supports quick switching of attachments such as breakers, grabs, and hydraulic drills.

Function Highlights: Its continuous operation ability improves the efficiency of metallurgical unpacking and improves the working environment. With multi - sensor fusion, it enables precise remote control.

Typical Scenarios: Handling of metal raw material packages, operations in high - temperature and high - dust areas

Core Parameters:

Weight: 2600kg

Power: Driven by a 30kW motor, with an output flow of 90L/min

Hydraulic System: Load - feedback pressure - compensated electro - hydraulic proportional valve

Function Highlights: Equipped with an SB302 hydraulic breaker, it has strong demolition capabilities. Suitable for high - risk scenarios such as tunnel excavation, secondary crushing in mines, and nuclear industries.

Cases: Maintenance of metallurgical furnaces, demolition of large buildings