At the highest level, rock breaking solutions fall into two broad categories, each with a distinct operational philosophy.

Stationary Rock Breaker Boom Systems: These are sophisticated, fixed-position installations comprising a boom arm, a hydraulic hammer (the actual breaker), and a central power unit. They are mounted on a pedestal, typically at a strategic choke point like the primary crusher feed or a grizzly.

Mobile Rock Breaker Machines: This category includes hydraulic hammers attached to excavators, backhoes, or dedicated mobile breaker carts. They are mobile, versatile, and can be moved to where the problem is.

The choice between a Rockbreaker Boom System and a mobile machine isn't just about preference; it's a fundamental decision impacting safety, efficiency, and total cost of ownership.

For high-volume, fixed-plant operations like quarries, mines, and large-scale aggregate processing plants, the stationary rock breaker is often the undisputed champion. Think of it as the automated, high-efficiency algorithm of the rock breaking world.

Maximized Crusher Uptime: This is the single biggest benefit. A rock breaker boom system is positioned directly over the crusher feed. When an oversize rock or bridge occurs, the operator can remotely fragment the blockage without stopping the feed conveyor. This eliminates costly downtime associated with plant stoppages, manual breaking, or waiting for a mobile unit.

Enhanced Safety: Safety is non-negotiable. Breaker booms keep operators in a safe, enclosed cabin, far from the crusher pit, falling debris, and dust. This removes the risk of accidents associated with operating a hammer on an excavator boom in a precarious position.

Improved Fragmentation: By breaking oversize rocks directly in the feeder or on the grizzly, these systems ensure a more consistent and optimally sized feed to the crusher. This reduces wear on the crusher liners and improves overall throughput.

Dedicated Power and Longevity: A stationary system has a dedicated hydraulic power unit (HPU) calibrated perfectly for the hammer, leading to more efficient energy use and reduced wear compared to an excavator's hydraulic system, which may not be perfectly optimized for the breaker.

Primary crusher feed stations.

Grizzly tops for scalp-and-break operations.

Underground mining ore passes and grizzlies.

Any application where blockages are frequent and plant throughput is critical.

The mobile rock breaker machine, typically an excavator-mounted hydraulic hammer, is the versatile, agile solution. It's the equivalent of a rapid-response team in the digital world—able to tackle a wide array of problems across a large site.

High Mobility: A single mobile breaker can service multiple locations across a large site, from the quarry face to the processing plant. If a boulder is found in a haul road or a different crusher level needs attention, the machine can be dispatched quickly.

Lower Initial Investment: For many small to medium-sized operations, the cost of a new rock breaker boom system can be prohibitive. Attaching a hammer to an existing excavator represents a significantly lower capital outlay.

Versatility: The same carrier machine (the excavator) can often be fitted with other attachments like buckets, grapples, or shears, making it a multi-purpose asset.

Small to medium quarries with infrequent blockages.

General construction and demolition sites.

Trench rock breaking.

Sites where breaking points are scattered and unpredictable.

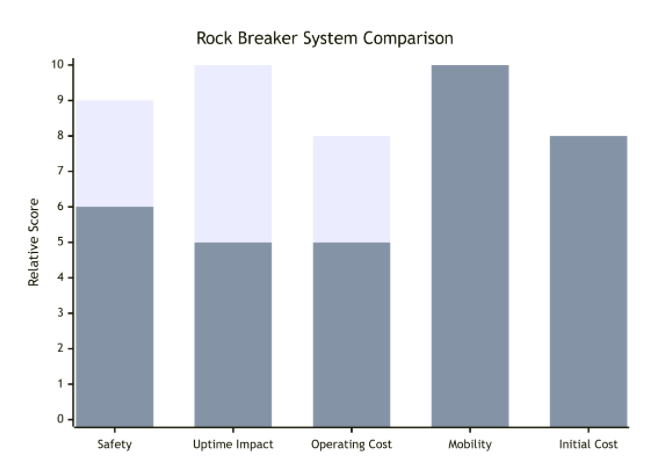

To move from anecdotal evidence to actionable data, let's compare these systems across several key performance indicators (KPIs) crucial for any operation manager.

The following chart illustrates a qualitative comparison based on industry data and operational reports:

Safety & Uptime: The Rockbreaker Boom System scores significantly higher. Its remote operation and fixed position directly translate to a safer environment and a direct, positive impact on plant uptime.

Operating Cost: While the initial cost is high for a stationary system, its operating cost over time is often lower. It reduces crusher wear, uses energy more efficiently, and, most importantly, prevents massive revenue loss from plant stoppages. A mobile machine, while cheaper upfront, can have higher long-term operating costs due to carrier machine fuel, maintenance, and the indirect cost of plant downtime during its mobilization and operation.

Mobility & Initial Cost: This is where the mobile rock breaker machine excels. Its flexibility and lower entry cost make it an attractive option for the right applications.

So, how do you choose? Answer these questions to build your own decision matrix:

What is the Frequency of Blockages?

High Frequency (Daily/Multiple times per day): A stationary rock breaker is almost certainly your best bet. The ROI from prevented downtime will be rapid.

Low Frequency (Weekly/Monthly): A mobile machine is likely more cost-effective.

What is the Cost of Downtime?

Calculate the lost revenue per hour when your primary crusher is stopped. For a large quarry, this can run into thousands of dollars per hour. If this number is high, the case for a rock breaker boom system becomes overwhelmingly strong.

What are Your Site's Safety Protocols?

If minimizing human exposure to hazardous areas is a top priority, the remote operation of Breaker Booms is a significant advantage.

What is Your Budget and Operational Scope?

For a single, focused task like keeping a primary crusher running, a dedicated system is superior. For a multi-faceted site with varied, infrequent breaking needs, a mobile machine offers better value.

The search for the perfect rock breaker is a quest for optimal fit, not a universal truth. The powerful, efficient, and safe Rockbreaker Boom System is the premium choice for high-volume, fixed-location operations where throughput and safety are king. In contrast, the versatile and mobile rock breaker machine remains the indispensable tool for dynamic sites with diverse and less frequent breaking needs.

Ultimately, the best rock breaker systems are those that are engineered into the process flow, not just added as an afterthought. By carefully evaluating your blockage frequency, downtime costs, and safety requirements, you can move beyond the simple question of "which one?" and instead arrive at the strategic answer of "this one, and here’s the data to prove it." Make your choice based on the long-term health of your operation, and you'll break through your productivity barriers, not just your rocks.